NEW

Important Product Categories of High-Voltage Parallel Capacitors

I. Introduction

High-voltage parallel capacitors are essential components in electrical systems, playing a critical role in energy storage, power factor correction, and voltage stabilization. These capacitors are designed to operate at high voltage levels, making them indispensable in various applications, including power generation, transmission, and distribution. This article aims to provide a comprehensive overview of high-voltage parallel capacitors, focusing on their key product categories, applications, and future trends.

II. Understanding High-Voltage Parallel Capacitors

A. Basic Principles of Capacitors

Capacitors are passive electrical components that store and release electrical energy. They consist of two conductive plates separated by an insulating material, known as a dielectric. The capacitance of a capacitor, measured in farads (F), indicates its ability to store charge. High-voltage capacitors are specifically designed to handle higher voltage ratings, typically exceeding 1,000 volts.

1. **Capacitance and Voltage Ratings**: The capacitance value determines how much charge a capacitor can store, while the voltage rating indicates the maximum voltage the capacitor can withstand without breaking down. High-voltage capacitors are engineered to maintain performance under extreme conditions.

2. **Energy Storage and Release Mechanism**: When a voltage is applied across the capacitor, an electric field develops between the plates, allowing the capacitor to store energy. When the voltage is removed, the stored energy can be released back into the circuit, providing a burst of power when needed.

B. Differences Between High-Voltage and Low-Voltage Capacitors

The primary difference between high-voltage and low-voltage capacitors lies in their construction and materials. High-voltage capacitors often use thicker dielectrics and more robust materials to withstand higher electric fields. Additionally, they are designed to minimize losses and ensure reliability in demanding environments.

C. Applications of High-Voltage Parallel Capacitors

High-voltage parallel capacitors are used in various applications, including:

- Power factor correction in industrial settings

- Smoothing voltage fluctuations in power supplies

- Energy storage in renewable energy systems

- Filtering harmonics in electrical networks

III. Key Product Categories of High-Voltage Parallel Capacitors

High-voltage parallel capacitors can be categorized into several types, each with unique characteristics, advantages, and applications.

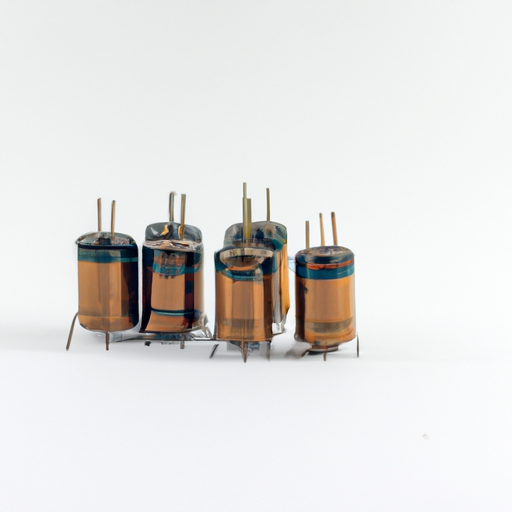

A. Film Capacitors

1. **Description and Characteristics**: Film capacitors use a thin plastic film as the dielectric material. They are known for their stability, low loss, and high insulation resistance.

2. **Advantages and Disadvantages**: Film capacitors offer excellent performance in terms of voltage stability and low self-inductance. However, they can be bulkier and more expensive than other types.

3. **Common Applications**: These capacitors are commonly used in power electronics, audio equipment, and power factor correction applications.

B. Ceramic Capacitors

1. **Description and Characteristics**: Ceramic capacitors use ceramic materials as the dielectric. They are compact and can handle high voltages, making them suitable for various applications.

2. **Advantages and Disadvantages**: Ceramic capacitors have a high capacitance-to-volume ratio and excellent frequency characteristics. However, they can be sensitive to temperature changes and mechanical stress.

3. **Common Applications**: They are widely used in RF applications, decoupling, and filtering in power supplies.

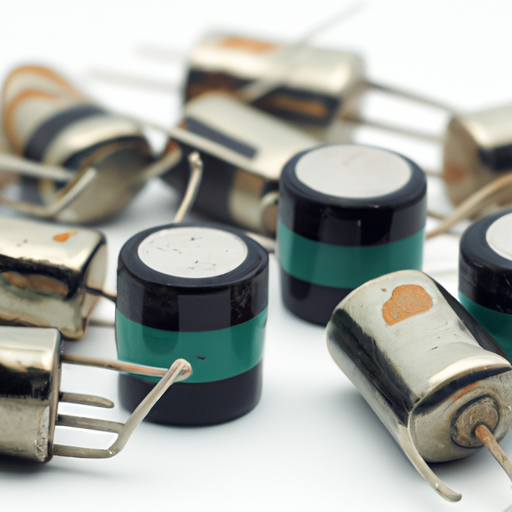

C. Electrolytic Capacitors

1. **Description and Characteristics**: Electrolytic capacitors use an electrolyte as one of the plates, allowing for higher capacitance values in a smaller size.

2. **Advantages and Disadvantages**: They are cost-effective and provide high capacitance, but they have a limited voltage rating and can be polarized, meaning they must be connected correctly in a circuit.

3. **Common Applications**: Electrolytic capacitors are often used in power supply circuits, energy storage, and smoothing applications.

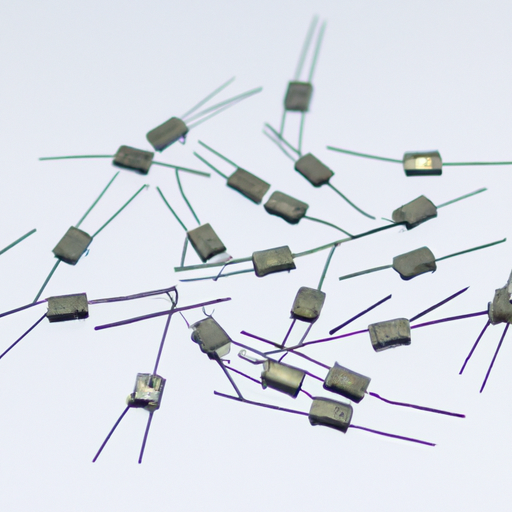

D. Tantalum Capacitors

1. **Description and Characteristics**: Tantalum capacitors use tantalum metal for the anode and are known for their high capacitance and reliability.

2. **Advantages and Disadvantages**: They offer excellent performance in terms of stability and reliability but can be more expensive than other types.

3. **Common Applications**: Tantalum capacitors are commonly used in military and aerospace applications, as well as in high-reliability electronics.

E. Supercapacitors

1. **Description and Characteristics**: Supercapacitors, also known as ultracapacitors, have a very high capacitance value and can store large amounts of energy.

2. **Advantages and Disadvantages**: They can charge and discharge rapidly, making them ideal for applications requiring quick bursts of energy. However, they have a lower voltage rating compared to other capacitors.

3. **Common Applications**: Supercapacitors are used in energy storage systems, backup power supplies, and regenerative braking systems in electric vehicles.

IV. Specialized High-Voltage Capacitors

In addition to the standard categories, there are specialized high-voltage capacitors designed for specific applications.

A. Power Factor Correction Capacitors

1. **Role in Electrical Systems**: Power factor correction capacitors help improve the efficiency of electrical systems by reducing reactive power and improving the power factor.

2. **Types and Specifications**: These capacitors can be either fixed or automatic, with specifications tailored to the specific needs of the electrical system.

B. Snubber Capacitors

1. **Purpose and Functionality**: Snubber capacitors are used to protect circuits from voltage spikes and transients, helping to extend the life of other components.

2. **Design Considerations**: The design of snubber capacitors must consider the specific voltage and current characteristics of the application.

C. DC Link Capacitors

1. **Importance in Power Electronics**: DC link capacitors are crucial in power electronics, providing energy storage and smoothing voltage fluctuations in converters and inverters.

2. **Key Features and Applications**: These capacitors must have high voltage ratings and low equivalent series resistance (ESR) to ensure efficient operation in high-frequency applications.

V. Factors Influencing the Selection of High-Voltage Parallel Capacitors

When selecting high-voltage parallel capacitors, several factors must be considered:

A. Voltage Rating and Capacitance Value

The voltage rating must exceed the maximum operating voltage of the application, while the capacitance value should meet the energy storage requirements.

B. Temperature and Environmental Considerations

Capacitors must be rated for the operating temperature range and environmental conditions, such as humidity and exposure to chemicals.

C. Frequency Response and Ripple Current

The frequency response of the capacitor is crucial for applications involving AC signals, while ripple current ratings ensure the capacitor can handle fluctuations without overheating.

D. Size and Form Factor

The physical size and form factor of the capacitor can impact its integration into existing systems, making it essential to consider space constraints.

E. Cost and Availability

Budget constraints and the availability of specific capacitor types can influence the selection process, requiring a balance between performance and cost.

VI. Future Trends in High-Voltage Parallel Capacitors

The field of high-voltage parallel capacitors is evolving, with several trends shaping the future of these components.

A. Advancements in Materials and Technology

Innovations in dielectric materials and manufacturing processes are leading to capacitors with improved performance, reliability, and efficiency.

B. Increasing Demand in Renewable Energy Applications

As the world shifts towards renewable energy sources, the demand for high-voltage capacitors in solar and wind energy systems is expected to grow.

C. Innovations in Energy Storage Solutions

The development of new energy storage technologies, including hybrid systems that combine capacitors with batteries, is paving the way for more efficient energy management solutions.

VII. Conclusion

High-voltage parallel capacitors are vital components in modern electrical systems, providing essential functions such as energy storage, power factor correction, and voltage stabilization. Understanding the various product categories, including film, ceramic, electrolytic, tantalum, and supercapacitors, is crucial for selecting the right capacitor for specific applications. As technology advances and the demand for renewable energy solutions increases, the future of high-voltage capacitors looks promising, with ongoing innovations set to enhance their performance and reliability.

VIII. References

- Academic Journals

- Industry Reports

- Manufacturer Specifications and Guidelines

This comprehensive overview of high-voltage parallel capacitors highlights their importance in electrical engineering and the various product categories available. By understanding these components, engineers and designers can make informed decisions that enhance the efficiency and reliability of electrical systems.

The Production Process of Mainstream Pulse Capacitors

I. Introduction

A. Definition of Pulse Capacitors

Pulse capacitors are specialized capacitors designed to handle high-voltage and high-current pulses. Unlike standard capacitors, which are typically used for filtering and smoothing applications, pulse capacitors are engineered to withstand rapid charge and discharge cycles, making them essential components in various high-performance electronic systems.

B. Importance of Pulse Capacitors in Electronics

In the realm of electronics, pulse capacitors play a critical role in applications such as power electronics, telecommunications, and automotive systems. Their ability to manage energy efficiently and reliably under extreme conditions makes them indispensable in modern technology. As electronic devices become more sophisticated, the demand for high-performance pulse capacitors continues to grow.

C. Overview of the Production Process

The production of pulse capacitors involves a meticulous process that includes material selection, design, assembly, and rigorous testing. This blog post will delve into the various stages of the production process, the raw materials used, and the challenges faced by manufacturers in creating these vital components.

II. Understanding Pulse Capacitors

A. Types of Pulse Capacitors

1. **Film Capacitors**: These capacitors use thin plastic films as dielectric materials. They are known for their stability, low loss, and high insulation resistance, making them suitable for high-frequency applications.

2. **Ceramic Capacitors**: Utilizing ceramic materials as dielectrics, these capacitors are compact and can handle high voltages. They are commonly used in RF applications and power supply circuits.

3. **Electrolytic Capacitors**: These capacitors use an electrolyte as one of their plates, allowing for higher capacitance values in a smaller size. They are often used in power supply circuits but are less suited for high-frequency applications.

B. Applications of Pulse Capacitors

1. **Power Electronics**: Pulse capacitors are crucial in power conversion systems, such as inverters and converters, where they help manage energy flow and improve efficiency.

2. **Telecommunications**: In telecommunications, pulse capacitors are used in signal processing and transmission systems, ensuring that signals remain clear and undistorted.

3. **Automotive Systems**: Modern vehicles rely on pulse capacitors for various functions, including energy storage in hybrid and electric vehicles, as well as in safety systems like airbags.

III. Raw Materials Used in Pulse Capacitor Production

A. Dielectric Materials

1. **Polypropylene**: Known for its excellent electrical properties and thermal stability, polypropylene is a common choice for film capacitors.

2. **Polyester**: This material offers good dielectric strength and is often used in applications where cost is a concern.

3. **Ceramic Materials**: Used primarily in ceramic capacitors, these materials provide high capacitance in a compact form factor.

B. Conductive Materials

1. **Aluminum Foil**: Widely used in electrolytic capacitors, aluminum foil serves as one of the conductive plates due to its excellent conductivity and cost-effectiveness.

2. **Copper**: Known for its superior conductivity, copper is often used in high-performance applications where efficiency is paramount.

3. **Silver**: While more expensive, silver is used in specialized applications due to its exceptional conductivity and resistance to corrosion.

C. Other Components

1. **Insulating Materials**: These materials are essential for preventing short circuits and ensuring the longevity of the capacitor.

2. **Adhesives and Sealants**: Used in the assembly process, these components help secure layers and protect against environmental factors.

IV. The Production Process

A. Design and Engineering

1. **Specifications and Requirements**: The production process begins with defining the specifications based on the intended application. This includes voltage ratings, capacitance values, and physical dimensions.

2. **Prototyping and Testing**: Engineers create prototypes to test the design under various conditions, ensuring that the capacitor meets performance standards.

B. Material Preparation

1. **Sourcing and Quality Control**: Raw materials are sourced from reliable suppliers, and quality control measures are implemented to ensure that they meet industry standards.

2. **Cutting and Shaping Dielectric and Conductive Materials**: The dielectric and conductive materials are cut and shaped according to the design specifications, preparing them for assembly.

C. Assembly Process

1. **Layering of Dielectric and Conductive Materials**: The assembly process involves layering the dielectric material between conductive layers, which is crucial for the capacitor's functionality.

2. **Winding or Stacking Techniques**: Depending on the type of capacitor, the layers may be wound into a cylindrical shape or stacked in a flat configuration.

3. **Connection of Terminals**: Terminals are connected to the conductive layers, allowing for electrical connections in the final application.

D. Encapsulation and Sealing

1. **Application of Protective Coatings**: A protective coating is applied to shield the capacitor from environmental factors such as moisture and dust.

2. **Sealing Techniques to Ensure Longevity**: Sealing methods are employed to prevent any ingress of contaminants, which could compromise the capacitor's performance.

E. Quality Assurance and Testing

1. **Electrical Testing**: Each capacitor undergoes rigorous electrical testing to ensure it meets the specified performance criteria.

2. **Environmental Testing**: Capacitors are subjected to various environmental conditions, such as temperature and humidity, to assess their reliability.

3. **Reliability Testing**: Long-term reliability tests are conducted to ensure that the capacitors can withstand the rigors of their intended applications.

V. Challenges in Pulse Capacitor Production

A. Material Limitations

The choice of materials can significantly impact the performance and cost of pulse capacitors. Manufacturers must balance performance with availability and cost-effectiveness.

B. Manufacturing Precision

The production of pulse capacitors requires high precision in manufacturing to ensure that they meet strict performance standards. Any deviation can lead to failures in the field.

C. Cost Management

As the demand for high-performance capacitors increases, manufacturers face pressure to manage costs while maintaining quality. This often involves investing in advanced manufacturing technologies.

D. Environmental Considerations

Manufacturers must also consider the environmental impact of their production processes, including waste management and the sustainability of raw materials.

VI. Innovations and Future Trends

A. Advances in Materials Science

Research into new materials, such as nanomaterials and advanced polymers, is paving the way for the development of more efficient and compact pulse capacitors.

B. Automation and Smart Manufacturing

The integration of automation and smart manufacturing technologies is enhancing production efficiency and precision, reducing costs, and improving quality.

C. Sustainability in Production

As environmental concerns grow, manufacturers are exploring sustainable practices, including the use of recyclable materials and energy-efficient production methods.

D. Emerging Applications and Markets

The rise of electric vehicles, renewable energy systems, and advanced telecommunications is driving demand for innovative pulse capacitors, creating new opportunities for manufacturers.

VII. Conclusion

A. Recap of the Production Process

The production of mainstream pulse capacitors is a complex process that involves careful material selection, precise engineering, and rigorous testing. Each stage is crucial to ensuring that the final product meets the high-performance standards required in modern electronics.

B. The Role of Pulse Capacitors in Modern Technology

Pulse capacitors are vital components in a wide range of applications, from power electronics to telecommunications and automotive systems. Their ability to manage energy efficiently under extreme conditions makes them indispensable in today's technology-driven world.

C. Future Outlook for the Industry

As technology continues to evolve, the demand for high-performance pulse capacitors will only increase. Innovations in materials and manufacturing processes will shape the future of the industry, ensuring that pulse capacitors remain at the forefront of electronic advancements.

VIII. References

A. Academic Journals

- Journal of Applied Physics

- IEEE Transactions on Power Electronics

B. Industry Reports

- Market Research Reports on Capacitor Technologies

- Industry Analysis on Electronic Components

C. Manufacturer Guidelines

- Technical Specifications from Leading Capacitor Manufacturers

- Best Practices for Capacitor Design and Production

---

This blog post provides a comprehensive overview of the production process of mainstream pulse capacitors, highlighting their significance in modern electronics and the challenges and innovations shaping the industry.

Important Patents in the Ceramic Capacitor Industry

I. Introduction

Ceramic capacitors are essential components in modern electronic devices, known for their reliability, stability, and versatility. These passive electronic components store and release electrical energy, playing a crucial role in filtering, decoupling, and timing applications. The ceramic capacitor industry is characterized by rapid technological advancements, and patents play a vital role in protecting innovations and fostering competition. This article explores the historical context, types, key patents, applications, and future trends in the ceramic capacitor industry.

II. Historical Context of Ceramic Capacitors

A. Early Development of Capacitors

The concept of capacitors dates back to the 18th century with the invention of the Leyden jar, the first device capable of storing electrical energy. However, it wasn't until the mid-20th century that ceramic capacitors began to emerge as a viable alternative to traditional capacitor technologies, such as electrolytic and film capacitors.

B. Evolution of Ceramic Capacitor Technology

The development of ceramic capacitors was driven by the need for smaller, more efficient components in the burgeoning electronics industry. The introduction of new dielectric materials and manufacturing techniques led to significant improvements in performance and reliability. As the demand for compact electronic devices grew, so did the innovation in ceramic capacitor technology.

C. Key Milestones in Patent Filings

The patent landscape for ceramic capacitors has evolved significantly over the decades. Early patents focused on basic manufacturing processes and material compositions, while more recent filings have addressed advanced technologies such as miniaturization and integration into complex electronic systems. These patents have not only protected the intellectual property of inventors but have also paved the way for advancements in the industry.

III. Types of Ceramic Capacitors

Ceramic capacitors are generally classified into two main categories: Class 1 and Class 2 capacitors, each with distinct characteristics and applications.

A. Class 1 Ceramic Capacitors

1. Characteristics and Applications

Class 1 ceramic capacitors, also known as NP0 (C0G) capacitors, are characterized by their stable capacitance over a wide temperature range and low loss. They are commonly used in precision applications, such as timing circuits and RF applications.

2. Notable Patents

Key patents in Class 1 ceramic capacitors often focus on the formulation of dielectric materials that enhance stability and performance. For instance, patents related to the development of high-purity barium titanate compositions have significantly improved the reliability of these capacitors.

B. Class 2 Ceramic Capacitors

1. Characteristics and Applications

Class 2 ceramic capacitors, including X7R and Y5V types, offer higher capacitance values in smaller packages but with less stability compared to Class 1 capacitors. They are widely used in applications where size and cost are critical, such as in consumer electronics.

2. Notable Patents

Patents in Class 2 ceramic capacitors often focus on improving dielectric properties and manufacturing processes. Innovations in multilayer ceramic capacitor (MLCC) technology have led to significant advancements in capacitance density, allowing for smaller and more efficient designs.

IV. Key Patents in Ceramic Capacitor Technology

A. Manufacturing Processes

1. Innovations in Material Composition

The development of new dielectric materials has been a focal point in ceramic capacitor patents. For example, patents that explore the use of alternative materials, such as lead-free ceramics, have gained importance due to environmental regulations and the push for sustainable manufacturing practices.

2. Notable Patents in Production Techniques

Innovations in production techniques, such as advanced sintering methods and multilayer stacking processes, have been patented to enhance the efficiency and performance of ceramic capacitors. These patents often detail methods for reducing defects and improving yield rates in manufacturing.

B. Dielectric Materials

1. Importance of Dielectric Properties

The dielectric material used in ceramic capacitors is crucial for determining their performance characteristics, including capacitance, voltage rating, and temperature stability. Patents related to dielectric materials often focus on enhancing these properties to meet the demands of modern electronics.

2. Key Patents Related to Dielectric Materials

Notable patents in this area include those that describe novel formulations of dielectric ceramics, such as barium titanate composites, which have been optimized for specific applications, including high-frequency circuits and power electronics.

C. Miniaturization and Integration

1. Trends in Miniaturization

As electronic devices continue to shrink in size, the demand for smaller and more efficient capacitors has increased. Miniaturization trends have led to the development of capacitors that can fit into increasingly compact spaces without sacrificing performance.

2. Patents Addressing Size Reduction and Integration

Patents addressing miniaturization often focus on innovative designs and manufacturing techniques that allow for the integration of capacitors into circuit boards and other components. These patents are critical for enabling the development of next-generation electronic devices.

V. Applications of Ceramic Capacitors

Ceramic capacitors are utilized across various industries, each with unique requirements and challenges.

A. Consumer Electronics

1. Role in Smartphones and Laptops

In consumer electronics, ceramic capacitors are integral to the functionality of smartphones, laptops, and other devices. They are used for decoupling, filtering, and energy storage, ensuring stable operation and performance.

2. Relevant Patents

Patents related to ceramic capacitors in consumer electronics often focus on improving performance in high-frequency applications and enhancing energy efficiency. Innovations in capacitor design and integration techniques are key areas of development.

B. Automotive Industry

1. Use in Electric Vehicles and Safety Systems

The automotive industry has increasingly adopted ceramic capacitors, particularly in electric vehicles (EVs) and advanced safety systems. These capacitors are essential for power management, signal processing, and energy storage.

2. Key Patents in Automotive Applications

Patents in this sector often address the unique challenges posed by automotive environments, such as temperature extremes and vibration. Innovations in capacitor design and materials that enhance reliability and performance in these conditions are critical.

C. Industrial Applications

1. Role in Automation and Control Systems

In industrial applications, ceramic capacitors are used in automation and control systems, where reliability and performance are paramount. They play a crucial role in signal processing, power supply, and energy storage.

2. Notable Patents in Industrial Use

Patents related to industrial applications often focus on enhancing the durability and performance of ceramic capacitors in harsh environments. Innovations in encapsulation techniques and materials are common themes in these patents.

VI. Future Trends and Innovations

A. Emerging Technologies in Ceramic Capacitors

The future of ceramic capacitors is likely to be shaped by emerging technologies, including advancements in nanotechnology and new dielectric materials. These innovations have the potential to significantly enhance the performance and capabilities of ceramic capacitors.

B. Anticipated Patent Developments

As the demand for more efficient and compact electronic devices continues to grow, we can expect a surge in patent filings related to ceramic capacitors. Innovations in manufacturing processes, materials, and designs will be at the forefront of this development.

C. Impact of Research and Development on the Industry

Ongoing research and development efforts will play a critical role in driving innovation in the ceramic capacitor industry. Collaboration between academia and industry will be essential for translating research breakthroughs into practical applications.

VII. Conclusion

In summary, patents are a cornerstone of the ceramic capacitor industry, protecting innovations that drive technological advancements. From the early development of capacitors to the latest trends in miniaturization and integration, patents have shaped the landscape of this vital industry. As we look to the future, the importance of innovation and intellectual property protection will continue to be paramount in ensuring the continued growth and evolution of ceramic capacitors.

VIII. References

A. Academic Journals

- Journal of Applied Physics

- IEEE Transactions on Dielectrics and Electrical Insulation

B. Patent Databases

- United States Patent and Trademark Office (USPTO)

- European Patent Office (EPO)

C. Industry Reports and Publications

- IC Insights

- Research and Markets Reports

This comprehensive overview of important patents in the ceramic capacitor industry highlights the critical role of innovation and intellectual property in shaping the future of electronic components. As technology continues to evolve, the ceramic capacitor industry will undoubtedly adapt, driven by the need for smaller, more efficient, and reliable components.

Current Situation of the Capacitor Series Industry

I. Introduction

Capacitors are fundamental components in electronic circuits, serving as energy storage devices that can release energy quickly when needed. They play a crucial role in various applications, from power supply smoothing to signal coupling and decoupling. The capacitor series industry is vital to modern technology, supporting the growth of sectors such as consumer electronics, automotive, telecommunications, and renewable energy. This blog post explores the current state of the capacitor series industry, examining its historical context, market dynamics, challenges, and future outlook.

II. Historical Context

A. Evolution of Capacitor Technology

The journey of capacitor technology began in the 18th century with the invention of the Leyden jar, one of the first capacitors. Over the years, various types of capacitors have been developed, including electrolytic, ceramic, film, and tantalum capacitors. Each type has unique characteristics that make it suitable for specific applications.

Key milestones in capacitor design and manufacturing include the introduction of electrolytic capacitors in the early 20th century, which allowed for higher capacitance values in a compact form. The development of ceramic capacitors in the mid-20th century further expanded the range of applications, particularly in high-frequency circuits.

B. Growth of the Capacitor Market Over the Decades

The capacitor market has experienced significant growth over the decades, driven by technological advancements and shifts in consumer demand. The rise of consumer electronics in the late 20th century, particularly with the advent of personal computers and mobile devices, created a surge in demand for capacitors. As technology continues to evolve, the capacitor industry has adapted to meet the changing needs of various sectors.

III. Types of Capacitors in the Industry

A. Electrolytic Capacitors

Electrolytic capacitors are known for their high capacitance values and are widely used in power supply applications. They are characterized by their polarized nature, which means they must be connected in a specific direction in a circuit. The demand for electrolytic capacitors remains strong, particularly in the automotive and industrial sectors, where they are used for energy storage and filtering applications.

B. Ceramic Capacitors

Ceramic capacitors are non-polarized and are favored for their stability and reliability. They are commonly used in high-frequency applications, such as RF circuits and decoupling in digital devices. The current market dynamics for ceramic capacitors are influenced by the growing demand for miniaturization in electronic devices, leading to the development of smaller and more efficient capacitor designs.

C. Film Capacitors

Film capacitors are known for their excellent performance in high-voltage applications and are often used in power electronics and audio equipment. They offer advantages such as low self-inductance and high insulation resistance. The film capacitor market is experiencing growth, driven by the increasing demand for renewable energy solutions and electric vehicles, where reliable energy storage is essential.

D. Tantalum Capacitors

Tantalum capacitors are recognized for their high capacitance-to-volume ratio and stability in extreme conditions. They are commonly used in military and aerospace applications, as well as in consumer electronics. The market position of tantalum capacitors is strong, but challenges such as material sourcing and price volatility can impact their availability.

IV. Market Analysis

A. Global Market Size and Growth Projections

The global capacitor market is projected to grow significantly in the coming years. According to industry reports, the market size was valued at approximately $25 billion in 2022 and is expected to reach around $40 billion by 2030, growing at a CAGR of about 6% during the forecast period. This growth is driven by the increasing demand for capacitors in various applications, including electric vehicles, renewable energy systems, and consumer electronics.

B. Major Players in the Capacitor Industry

The capacitor industry is characterized by a competitive landscape with several key players dominating the market. Leading manufacturers include Murata Manufacturing Co., Ltd., Vishay Intertechnology, Inc., KEMET Corporation, and Nichicon Corporation. These companies are continuously innovating and expanding their product offerings to maintain their market share.

C. Emerging Trends and Innovations

Technological advancements are shaping the future of the capacitor industry. Innovations such as the development of supercapacitors, which offer higher energy density and faster charging times, are gaining traction. Additionally, sustainability is becoming a significant focus, with manufacturers exploring eco-friendly materials and production processes to reduce their environmental impact.

V. Challenges Facing the Capacitor Series Industry

A. Supply Chain Disruptions

The capacitor industry has faced significant challenges due to supply chain disruptions, particularly in the wake of global events such as the COVID-19 pandemic and geopolitical tensions. These disruptions have led to material shortages, affecting production timelines and costs. Manufacturers are now seeking to diversify their supply chains and invest in local sourcing to mitigate these risks.

B. Regulatory and Compliance Issues

As environmental concerns grow, regulatory and compliance issues are becoming increasingly important for the capacitor industry. Manufacturers must adhere to stringent environmental regulations and safety standards, which can impact production processes and costs. Staying compliant while maintaining profitability is a challenge that industry stakeholders must navigate.

C. Competition from Alternative Technologies

The rise of alternative energy storage solutions, such as supercapacitors and batteries, poses a competitive threat to traditional capacitors. As these technologies continue to evolve, the capacitor industry must adapt and innovate to remain relevant. This may involve investing in research and development to enhance capacitor performance and explore new applications.

VI. Future Outlook

A. Predictions for the Capacitor Market

The future of the capacitor market looks promising, with several growth areas and applications expected to emerge. The increasing adoption of electric vehicles and renewable energy systems will drive demand for high-performance capacitors. Additionally, advancements in technology, such as the Internet of Things (IoT) and 5G networks, will create new opportunities for capacitor applications in smart devices and communication systems.

B. Strategic Recommendations for Industry Stakeholders

To thrive in the evolving capacitor market, industry stakeholders should consider several strategic recommendations. Investing in research and development is crucial to drive innovation and improve capacitor performance. Collaboration and partnerships with technology companies can also foster innovation and open new avenues for growth.

VII. Conclusion

In summary, the capacitor series industry plays a vital role in modern technology, supporting various applications across multiple sectors. The industry has evolved significantly over the years, adapting to changing consumer demands and technological advancements. While challenges such as supply chain disruptions and competition from alternative technologies exist, the future outlook for the capacitor market remains positive. By embracing innovation and sustainability, the capacitor industry can continue to thrive and contribute to the advancement of technology in the years to come.

What Product Types Do Capacitor Principles Include?

I. Introduction

Capacitors are fundamental components in electronic circuits, playing a crucial role in the storage and management of electrical energy. Defined as passive electronic components that store energy in an electric field, capacitors are essential for various applications, from smoothing out voltage fluctuations to enabling signal processing. This article aims to explore the principles of capacitors, the different types available, and their applications across various industries.

II. Basic Principles of Capacitors

A. Explanation of Capacitance

Capacitance is the ability of a capacitor to store an electrical charge. It is defined as the ratio of the electric charge (Q) stored on one plate of the capacitor to the voltage (V) across the plates. The unit of capacitance is the Farad (F), which is a large unit; in practice, capacitors are often rated in microfarads (µF), nanofarads (nF), or picofarads (pF).

Several factors affect capacitance:

1. **Surface Area**: The larger the surface area of the plates, the greater the capacitance.

2. **Distance**: The closer the plates are to each other, the higher the capacitance, as the electric field strength increases.

3. **Dielectric Material**: The type of insulating material (dielectric) placed between the plates influences capacitance. Different materials have varying dielectric constants, affecting the capacitor's ability to store charge.

B. How Capacitors Store and Release Energy

Capacitors store energy in the form of an electric field created between two conductive plates separated by a dielectric. When a voltage is applied, electrons accumulate on one plate, creating a negative charge, while the other plate loses electrons, resulting in a positive charge. This stored energy can be released when the circuit requires it, making capacitors vital for energy management in electronic devices.

C. Types of Capacitors Based on Construction and Materials

Capacitors can be categorized based on their construction and the materials used. This classification leads to various types of capacitors, each with unique characteristics and applications.

III. Major Types of Capacitors

A. Ceramic Capacitors

Ceramic capacitors are made from ceramic materials and are widely used due to their small size and reliability. They are available in various capacitance values and voltage ratings.

**Characteristics and Applications**: Ceramic capacitors are often used in high-frequency applications, such as RF circuits, and in decoupling and filtering applications in power supplies.

**Advantages and Disadvantages**: They are stable, have low losses, and are inexpensive. However, they can have a limited capacitance range and may exhibit voltage coefficient effects.

B. Electrolytic Capacitors

Electrolytic capacitors are polarized capacitors that use an electrolyte as one of their plates. They are known for their high capacitance values.

**Characteristics and Applications**: Commonly used in power supply circuits for smoothing and filtering, electrolytic capacitors are essential in applications requiring large capacitance.

**Advantages and Disadvantages**: They offer high capacitance in a small volume but are polarized, meaning they must be connected correctly in a circuit. They also have a limited lifespan and can fail if subjected to high temperatures.

C. Tantalum Capacitors

Tantalum capacitors are another type of electrolytic capacitor, known for their stability and reliability.

**Characteristics and Applications**: They are used in applications where size and performance are critical, such as in mobile devices and aerospace electronics.

**Advantages and Disadvantages**: Tantalum capacitors have a high capacitance-to-volume ratio and excellent frequency characteristics. However, they are more expensive than aluminum electrolytic capacitors and can be sensitive to voltage spikes.

D. Film Capacitors

Film capacitors use a thin plastic film as the dielectric material. They are known for their stability and low loss.

**Characteristics and Applications**: Commonly used in audio applications, timing circuits, and power electronics, film capacitors are favored for their reliability.

**Advantages and Disadvantages**: They have a long lifespan and excellent performance but can be bulkier than other types of capacitors.

E. Supercapacitors

Supercapacitors, also known as ultracapacitors, have a very high capacitance value and are used for energy storage applications.

**Characteristics and Applications**: They are used in applications requiring rapid charge and discharge cycles, such as in regenerative braking systems and energy storage for renewable energy systems.

**Advantages and Disadvantages**: Supercapacitors can charge and discharge quickly and have a long cycle life. However, they have lower energy density compared to batteries.

F. Mica Capacitors

Mica capacitors use mica as the dielectric material and are known for their high precision and stability.

**Characteristics and Applications**: They are often used in RF applications and precision timing circuits.

**Advantages and Disadvantages**: Mica capacitors have excellent temperature stability and low losses but can be more expensive and larger than other types.

G. Aluminum and Paper Capacitors

Aluminum and paper capacitors are older technologies that are still used in specific applications.

**Characteristics and Applications**: They are often found in older electronic devices and applications where cost is a significant factor.

**Advantages and Disadvantages**: They are inexpensive but can have lower performance compared to modern capacitors.

IV. Specialized Capacitors

A. Power Capacitors

Power capacitors are designed for use in power systems to improve power factor and voltage stability.

**Definition and Applications**: They are used in industrial applications, such as in substations and power distribution systems.

B. RF Capacitors

RF capacitors are designed for high-frequency applications, such as in radio transmitters and receivers.

**Definition and Applications**: They are used in circuits that operate at radio frequencies, where low losses and stability are critical.

C. Motor Start Capacitors

Motor start capacitors provide the necessary torque to start electric motors.

**Definition and Applications**: They are commonly used in single-phase induction motors, such as those found in air conditioners and refrigerators.

D. Timing Capacitors

Timing capacitors are used in timing circuits to control the timing of events.

**Definition and Applications**: They are found in applications such as oscillators and timers, where precise timing is essential.

V. Emerging Technologies and Innovations

A. Development of New Materials for Capacitors

Research is ongoing into new dielectric materials that can enhance the performance of capacitors, leading to higher capacitance values and improved efficiency.

B. Advancements in Capacitor Design and Efficiency

Innovations in capacitor design, such as the development of multilayer capacitors, are improving energy density and reducing size.

C. Future Trends in Capacitor Technology

The future of capacitor technology may include the integration of capacitors with other energy storage systems, such as batteries, to create hybrid energy storage solutions.

VI. Applications of Capacitors in Various Industries

A. Consumer Electronics

Capacitors are ubiquitous in consumer electronics, used in everything from smartphones to televisions for filtering and energy storage.

B. Automotive Industry

In the automotive sector, capacitors are used in power management systems, infotainment systems, and electric vehicles.

C. Renewable Energy Systems

Capacitors play a vital role in renewable energy systems, such as solar inverters and wind turbines, for energy storage and management.

D. Telecommunications

In telecommunications, capacitors are used in signal processing and filtering applications to ensure clear communication.

E. Industrial Automation

Capacitors are essential in industrial automation for motor control, power factor correction, and energy storage.

VII. Conclusion

Capacitors are integral to modern electronics, with various types designed to meet specific needs across multiple industries. From ceramic and electrolytic capacitors to specialized types like supercapacitors and motor start capacitors, each type has unique characteristics that make it suitable for particular applications. As technology advances, the development of new materials and designs will continue to enhance capacitor performance, ensuring their relevance in the ever-evolving landscape of electronics.

VIII. References

A comprehensive list of academic papers, articles, and books can be provided for further reading on the principles, types, and applications of capacitors. This will help readers deepen their understanding of this essential electronic component.

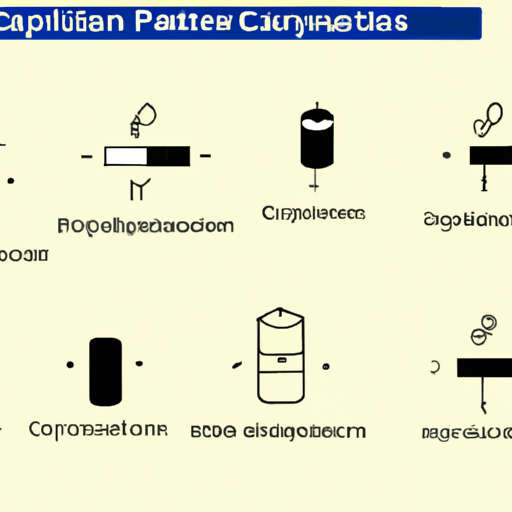

What is the Difference Between Mainstream Capacitor Symbol Models?

I. Introduction

Capacitors are fundamental components in electronic circuits, playing a crucial role in energy storage, filtering, and timing applications. They store electrical energy in an electric field, allowing them to release it when needed. Understanding the various types of capacitors and their representations in schematics is essential for anyone involved in electronics, from hobbyists to professional engineers. This blog post will explore the differences between mainstream capacitor symbol models, shedding light on their significance in circuit design.

II. Understanding Capacitor Basics

A. What is a Capacitor?

A capacitor is a passive electronic component that stores energy in an electric field. It consists of two conductive plates separated by an insulating material known as a dielectric. When a voltage is applied across the plates, an electric field is created, allowing the capacitor to store charge.

1. Definition and Function

The primary function of a capacitor is to store and release electrical energy. This capability makes capacitors essential in various applications, including power supply smoothing, signal coupling and decoupling, and timing circuits.

2. Types of Capacitors

There are several types of capacitors, each with unique characteristics and applications:

Ceramic Capacitors: Known for their small size and stability, ceramic capacitors are widely used in high-frequency applications.

Electrolytic Capacitors: These capacitors are polarized and typically used for larger capacitance values in power supply circuits.

Tantalum Capacitors: Similar to electrolytic capacitors but with better performance in terms of stability and reliability, tantalum capacitors are often used in compact electronic devices.

B. Key Parameters of Capacitors

Understanding the key parameters of capacitors is essential for selecting the right component for a specific application:

1. Capacitance

Measured in farads (F), capacitance indicates the amount of charge a capacitor can store per volt of electrical potential.

2. Voltage Rating

The voltage rating specifies the maximum voltage a capacitor can handle without breaking down. Exceeding this rating can lead to failure.

3. Equivalent Series Resistance (ESR)

ESR is a measure of the internal resistance of a capacitor, affecting its efficiency and performance, especially in high-frequency applications.

4. Temperature Coefficient

This parameter indicates how the capacitance value changes with temperature, which is crucial for applications requiring stable performance across varying conditions.

III. The Role of Symbols in Circuit Design

A. Importance of Schematic Symbols

Schematic symbols are graphical representations of electronic components used in circuit diagrams. They provide a standardized way to convey information about components, making it easier for engineers and technicians to understand and communicate circuit designs.

B. Standardization of Symbols in Electronics

Standardization ensures that symbols are universally recognized, reducing confusion and errors in circuit interpretation. Organizations like the Institute of Electrical and Electronics Engineers (IEEE) and the International Electrotechnical Commission (IEC) have established guidelines for these symbols.

C. How Symbols Convey Information About Components

Each symbol conveys specific information about the component it represents, including its type, function, and characteristics. For capacitors, different symbols indicate whether they are polarized, non-polarized, variable, or supercapacitors.

IV. Mainstream Capacitor Symbol Models

A. Basic Capacitor Symbol

The basic capacitor symbol consists of two parallel lines representing the plates, with a gap between them indicating the dielectric. This symbol is used for general-purpose capacitors.

1. Description and Usage

The basic capacitor symbol is versatile and can represent various capacitor types, but it does not convey information about polarity or specific characteristics.

2. Variations in Representation

In some schematics, the basic symbol may include additional markings to indicate specific features, such as capacitance value or voltage rating.

B. Polarized Capacitor Symbol

Polarized capacitors, such as electrolytic capacitors, have a specific orientation in circuits. Their symbol typically includes a plus (+) sign to indicate the positive terminal.

1. Definition and Significance

Polarized capacitors must be connected in the correct orientation to function properly. Incorrect connections can lead to failure or damage.

2. Common Applications

These capacitors are commonly used in power supply circuits, audio equipment, and other applications where large capacitance values are required.

C. Non-Polarized Capacitor Symbol

Non-polarized capacitors can be connected in either direction, making them more versatile than polarized types. Their symbol resembles the basic capacitor symbol but may have additional markings to indicate their non-polarized nature.

1. Characteristics and Uses

Non-polarized capacitors are often used in AC applications, such as audio crossover networks and timing circuits.

2. Differences from Polarized Symbols

The absence of polarity indicators in the non-polarized symbol highlights its versatility, while the polarized symbol emphasizes the importance of correct orientation.

D. Variable Capacitor Symbol

Variable capacitors are adjustable components used in tuning circuits, such as radios. Their symbol often includes a curved line or arrow to indicate the adjustable nature.

1. Explanation and Applications

Variable capacitors allow for tuning to different frequencies, making them essential in applications like radio transmitters and receivers.

2. Importance in Tuning Circuits

The ability to adjust capacitance values enables precise control over circuit behavior, making variable capacitors crucial in many electronic devices.

E. Supercapacitor Symbol

Supercapacitors, also known as ultracapacitors, have a unique symbol that distinguishes them from traditional capacitors. Their symbol may include additional markings to indicate their high capacitance and energy storage capabilities.

1. Definition and Unique Features

Supercapacitors can store significantly more energy than standard capacitors, making them suitable for applications requiring rapid charge and discharge cycles.

2. Applications in Energy Storage

These components are increasingly used in energy storage systems, backup power supplies, and electric vehicles due to their high energy density and fast charging capabilities.

V. Differences Between Symbol Models

A. Visual Distinctions

1. Shape and Orientation

The shape and orientation of capacitor symbols vary based on their type. For example, polarized capacitors have a distinct plus sign, while variable capacitors feature arrows or curves.

2. Additional Markings

Some symbols include additional markings, such as capacitance values or voltage ratings, providing more information about the component.

B. Functional Implications

1. How Symbol Differences Affect Circuit Behavior

The differences in symbols reflect the functional characteristics of the capacitors. For instance, using a polarized symbol in a non-polarized application can lead to circuit failure.

2. Importance of Correct Symbol Usage in Design

Using the correct symbol is crucial for accurate circuit design and analysis. Misinterpretation can result in design flaws and operational issues.

C. Contextual Usage

1. Situations Where Specific Symbols Are Preferred

Certain applications may require specific symbols to convey essential information. For example, tuning circuits will typically use variable capacitor symbols.

2. Industry Standards and Practices

Adhering to industry standards for schematic symbols ensures consistency and clarity in circuit design, facilitating collaboration among engineers and technicians.

VI. Common Misconceptions

A. Misunderstanding Capacitor Types and Symbols

Many individuals may confuse different capacitor types and their corresponding symbols, leading to incorrect assumptions about their functionality.

B. Importance of Recognizing Symbol Variations

Recognizing the variations in capacitor symbols is vital for accurate circuit interpretation and design. Each symbol conveys specific information that can impact circuit performance.

C. Consequences of Incorrect Symbol Interpretation

Misinterpreting capacitor symbols can lead to design errors, component failures, and ultimately, project delays or increased costs.

VII. Conclusion

Understanding the differences between mainstream capacitor symbol models is essential for anyone involved in electronics. Accurate representation of capacitors in schematics not only aids in circuit design but also ensures proper functionality and reliability. As technology continues to evolve, the role of capacitors in modern electronics remains critical. We encourage further study and exploration of this fascinating topic, as a solid grasp of capacitor symbols can significantly enhance your skills in electronic design.

VIII. References

- Suggested readings and resources for further learning about capacitors and their applications.

- Industry standards and guidelines for schematic symbols, including IEEE and IEC documentation.

By delving into the world of capacitors and their symbols, you can enhance your understanding of electronic circuits and improve your design capabilities. Whether you're a beginner or an experienced engineer, mastering these concepts will undoubtedly benefit your work in the field of electronics.

Important Product Categories of Capacitors

I. Introduction

Capacitors are fundamental components in electronic circuits, playing a crucial role in energy storage, filtering, and signal processing. They are passive electrical devices that store energy in an electric field, allowing them to release that energy when needed. The importance of capacitors cannot be overstated, as they are integral to the functioning of a wide range of electronic devices, from simple circuits to complex systems in telecommunications, automotive, and consumer electronics. This article aims to provide an overview of the various product categories of capacitors, their characteristics, applications, and the emerging trends in capacitor technology.

II. Basic Principles of Capacitors

A. How Capacitors Work

Capacitors operate on the principle of charge storage. When a voltage is applied across the terminals of a capacitor, an electric field is created, allowing the capacitor to store electrical energy. The amount of charge a capacitor can store is defined by its capacitance, measured in farads (F). Capacitance is influenced by several factors, including the surface area of the conductive plates, the distance between them, and the dielectric material used.

B. Key Parameters Affecting Capacitor Performance

1. **Voltage Rating**: This is the maximum voltage a capacitor can handle before it risks breakdown. Exceeding this rating can lead to capacitor failure, which can damage the circuit.

2. **Temperature Coefficient**: Capacitors are sensitive to temperature changes, which can affect their capacitance and performance. The temperature coefficient indicates how much the capacitance changes with temperature.

3. **Equivalent Series Resistance (ESR)**: This parameter represents the internal resistance of the capacitor, which can affect its efficiency, especially in high-frequency applications.

III. Major Product Categories of Capacitors

A. Ceramic Capacitors

Ceramic capacitors are among the most widely used capacitors in electronic circuits. They are made from ceramic materials and are classified into two main types: Class 1 and Class 2.

1. **Types**:

- **Class 1** capacitors offer stable capacitance over a wide temperature range and are typically used in precision applications.

- **Class 2** capacitors have higher capacitance values but exhibit more significant changes in capacitance with temperature and voltage.

2. **Applications**: Commonly used in decoupling, filtering, and timing applications.

3. **Advantages and Disadvantages**: They are small, reliable, and cost-effective but can have lower capacitance values compared to other types.

B. Electrolytic Capacitors

Electrolytic capacitors are polarized capacitors that use an electrolyte to achieve a larger capacitance value.

1. **Types**:

- **Aluminum electrolytic capacitors** are the most common, while **tantalum capacitors** offer higher stability and reliability.

2. **Applications**: Widely used in power supply circuits, audio equipment, and energy storage applications.

3. **Advantages and Disadvantages**: They provide high capacitance in a small volume but are sensitive to polarity and can have a shorter lifespan compared to other types.

C. Film Capacitors

Film capacitors use a thin plastic film as the dielectric material.

1. **Types**: Common types include polyester, polypropylene, and polystyrene capacitors.

2. **Applications**: Used in audio circuits, power electronics, and timing applications.

3. **Advantages and Disadvantages**: They offer excellent stability and low ESR but can be bulkier than ceramic capacitors.

D. Supercapacitors (Ultracapacitors)

Supercapacitors are high-capacity capacitors that bridge the gap between electrolytic capacitors and rechargeable batteries.

1. **Definition and Working Principle**: They store energy through electrostatic charge separation, allowing for rapid charge and discharge cycles.

2. **Applications**: Used in energy storage systems, backup power supplies, and regenerative braking systems in electric vehicles.

3. **Advantages and Disadvantages**: They have a high energy density and long cycle life but lower voltage ratings compared to traditional capacitors.

E. Mica Capacitors

Mica capacitors use natural mica as the dielectric material.

1. **Characteristics and Applications**: Known for their stability and reliability, they are often used in high-frequency applications and precision circuits.

2. **Advantages and Disadvantages**: They offer excellent performance but can be more expensive and larger than other types.

F. Paper Capacitors

Historically significant, paper capacitors use paper as the dielectric material.

1. **Historical Significance and Current Use**: Once widely used, they are now less common but still found in vintage electronics and specific applications.

2. **Advantages and Disadvantages**: They are relatively inexpensive but can be less reliable and have lower capacitance values.

G. Variable Capacitors

Variable capacitors allow for adjustable capacitance.

1. **Types**: Common types include air-gap capacitors and trimmer capacitors.

2. **Applications**: Used in tuning circuits, radio transmitters, and receivers.

3. **Advantages and Disadvantages**: They provide flexibility in circuit design but can be more complex to implement.

IV. Specialized Capacitors

A. High-Voltage Capacitors

High-voltage capacitors are designed to operate in power systems where high voltage levels are present.

1. **Applications in Power Systems**: Used in power transmission, energy storage, and power factor correction.

2. **Design Considerations**: Must be designed to withstand high voltages and have robust insulation.

B. RF Capacitors

RF capacitors are specifically designed for radio frequency applications.

1. **Importance in Radio Frequency Applications**: They are crucial for tuning and filtering in RF circuits.

2. **Characteristics and Design**: Must have low ESR and high-frequency stability.

C. Automotive Capacitors

Automotive capacitors are tailored for use in automotive electronics.

1. **Role in Automotive Electronics**: Used in power management, infotainment systems, and safety features.

2. **Specific Requirements and Standards**: Must meet stringent automotive standards for reliability and performance.

V. Emerging Trends in Capacitor Technology

A. Miniaturization and Integration

As electronic devices become smaller and more compact, there is a growing demand for miniaturized capacitors that can fit into tight spaces without sacrificing performance.

B. Development of New Materials

Research is ongoing into new dielectric materials that can enhance capacitance, reduce size, and improve performance.

C. Environmental Considerations and Recycling

With increasing awareness of environmental issues, there is a push for capacitors that are more sustainable and easier to recycle.

VI. Conclusion

In summary, capacitors are essential components in modern electronics, with various types designed for specific applications. Understanding the different product categories, their characteristics, and their applications is crucial for selecting the right capacitor for any given project. As technology continues to evolve, the future of capacitor technology looks promising, with advancements in materials, miniaturization, and sustainability paving the way for more efficient and effective electronic devices.

VII. References

For further exploration of capacitors and their applications, consider the following resources:

1. "Capacitors: Technology and Applications" by John Smith

2. "The Art of Electronics" by Paul Horowitz and Winfield Hill

3. Online resources such as IEEE Xplore and Electronics Tutorials for up-to-date research and articles on capacitor technology.

This comprehensive overview of capacitor categories provides a solid foundation for understanding their role in electronics and the ongoing developments in the field.

Common Production Processes for High-Voltage Capacitors

I. Introduction

High-voltage capacitors are essential components in various electrical and electronic systems, playing a critical role in energy storage, power conditioning, and signal processing. These capacitors are designed to operate at voltages significantly higher than standard capacitors, making them indispensable in applications such as power transmission, renewable energy systems, and industrial machinery. Understanding the production processes involved in creating high-voltage capacitors is crucial for manufacturers and engineers alike, as it ensures the reliability and efficiency of these vital components.

II. Types of High-Voltage Capacitors

High-voltage capacitors come in several types, each with unique characteristics and applications:

A. Ceramic Capacitors

Ceramic capacitors are known for their stability and reliability. They are often used in high-frequency applications due to their low equivalent series resistance (ESR) and high dielectric strength.

B. Film Capacitors

Film capacitors utilize thin plastic films as dielectrics. They are favored for their excellent performance in high-voltage applications, particularly in power electronics and audio equipment.

C. Electrolytic Capacitors

Electrolytic capacitors are polarized devices that offer high capacitance values in a compact form. They are commonly used in power supply circuits but require careful handling due to their voltage limitations.

D. Tantalum Capacitors

Tantalum capacitors are known for their high capacitance-to-volume ratio and stability. They are often used in military and aerospace applications where reliability is paramount.

E. Comparison of Different Types

Each type of high-voltage capacitor has its advantages and disadvantages, making them suitable for specific applications. Understanding these differences is essential for selecting the right capacitor for a given application.

III. Raw Materials

A. Overview of Materials Used in High-Voltage Capacitors

The production of high-voltage capacitors relies on various raw materials, primarily focusing on dielectric and conductive materials.

1. Dielectric Materials

Dielectric materials are crucial for capacitor performance. Common dielectrics include ceramic, polyester, polypropylene, and tantalum oxide, each offering different electrical properties.

2. Conductive Materials

Conductive materials, such as aluminum and copper, are used for electrodes. The choice of conductive material affects the capacitor's efficiency and performance.

B. Quality Control of Raw Materials

Ensuring the quality of raw materials is vital for the performance and reliability of high-voltage capacitors. Manufacturers implement stringent quality control measures to test and verify the properties of dielectric and conductive materials.

C. Sourcing and Sustainability Considerations

Sourcing raw materials sustainably is becoming increasingly important. Manufacturers are exploring eco-friendly alternatives and practices to minimize their environmental impact.

IV. Production Processes

A. Design and Engineering

The production of high-voltage capacitors begins with design and engineering, where specifications and requirements are established.

1. Specifications and Requirements

Engineers define the electrical, mechanical, and thermal specifications based on the intended application, ensuring the capacitor meets performance standards.

2. Simulation and Modeling

Advanced simulation and modeling techniques are employed to predict the behavior of the capacitor under various conditions, allowing for optimization before physical production begins.

B. Dielectric Layer Formation

The dielectric layer is a critical component of high-voltage capacitors, and its formation involves several methods:

1. Methods of Dielectric Layer Production

Coating: A thin layer of dielectric material is applied to a substrate using techniques such as spray coating or dip coating.

Laminating: Multiple layers of dielectric materials are bonded together to enhance performance.

Pressing: Dielectric materials are pressed into shape under high pressure to achieve the desired thickness and density.

C. Electrode Preparation

Electrode preparation is another crucial step in the production process.

1. Material Selection

The choice of electrode material impacts the capacitor's performance. Common materials include aluminum and copper, selected for their conductivity and compatibility with the dielectric.

2. Fabrication Techniques

Etching: This technique is used to create precise patterns on the electrode surface, enhancing the capacitor's performance.

Stamping: Stamping is employed to cut and shape electrodes from larger sheets of conductive material.

D. Assembly

The assembly process involves several steps to create the final capacitor product.

1. Layer Stacking

The dielectric layers and electrodes are stacked in a specific order to form the capacitor structure, ensuring optimal performance.

2. Connection of Electrodes

Electrodes are connected to ensure proper electrical contact, which is critical for the capacitor's functionality.

3. Encapsulation

The assembled capacitor is encapsulated to protect it from environmental factors and mechanical stress, ensuring longevity and reliability.

E. Testing and Quality Assurance

Quality assurance is a vital part of the production process, involving various testing methods.

1. Electrical Testing

Electrical tests are conducted to verify the capacitor's performance, including capacitance, voltage rating, and leakage current.

2. Mechanical Testing

Mechanical tests assess the capacitor's durability and resistance to physical stress, ensuring it can withstand operational conditions.

3. Environmental Testing

Environmental tests evaluate the capacitor's performance under different temperature and humidity conditions, ensuring reliability in various environments.

V. Advanced Manufacturing Techniques

A. Automation in Production

Automation is increasingly being integrated into the production of high-voltage capacitors, enhancing efficiency and precision. Automated systems can streamline processes, reduce human error, and increase production rates.

B. Use of Nanotechnology

Nanotechnology is being explored to improve the performance of dielectric materials, potentially leading to capacitors with higher energy densities and improved thermal stability.

C. Innovations in Materials Science

Ongoing research in materials science is leading to the development of new dielectric and conductive materials that can enhance the performance and reliability of high-voltage capacitors.

VI. Challenges in Production

A. Managing High-Voltage Requirements

Producing capacitors that can safely handle high voltages presents unique challenges, including ensuring dielectric breakdown strength and minimizing leakage currents.

B. Ensuring Reliability and Longevity

Manufacturers must focus on creating capacitors that not only perform well initially but also maintain their performance over time, addressing issues such as aging and environmental degradation.

C. Addressing Environmental Concerns

As sustainability becomes a priority, manufacturers face the challenge of reducing waste and energy consumption in the production process while ensuring compliance with environmental regulations.

VII. Future Trends in High-Voltage Capacitor Production

A. Emerging Technologies

The future of high-voltage capacitor production will likely see the integration of emerging technologies, such as advanced materials and smart manufacturing techniques, to enhance performance and efficiency.

B. Market Demands and Shifts

As industries evolve, the demand for high-voltage capacitors will shift, requiring manufacturers to adapt their production processes to meet new requirements and applications.

C. Sustainability Initiatives

Sustainability initiatives will play a crucial role in shaping the future of capacitor production, with manufacturers focusing on eco-friendly materials and processes to minimize their environmental impact.

VIII. Conclusion

High-voltage capacitors are vital components in modern electrical systems, and understanding their production processes is essential for ensuring their reliability and performance. From raw materials to advanced manufacturing techniques, each step in the production process contributes to the final product's quality. As technology continues to evolve, the future of high-voltage capacitor manufacturing will be shaped by emerging trends, sustainability initiatives, and the ongoing quest for improved performance.

IX. References

- Academic journals on capacitor technology and materials science.

- Industry reports detailing market trends and innovations in capacitor manufacturing.

- Manufacturer guidelines and standards for high-voltage capacitors.

This comprehensive overview of the production processes for high-voltage capacitors highlights the complexity and importance of these components in various applications, providing valuable insights for manufacturers and engineers alike.

What are the Advantages of Capacitor Bank Products?

I. Introduction

In the realm of electrical systems, capacitor banks play a pivotal role in enhancing performance and efficiency. A capacitor bank is a group of several capacitors connected in parallel or series, designed to store and release electrical energy. These devices are essential for improving power quality, stabilizing voltage levels, and optimizing energy consumption in various applications. This blog post will delve into the numerous advantages of capacitor bank products, highlighting their significance in modern electrical systems.

II. Understanding Capacitor Banks

A. Explanation of How Capacitor Banks Work

Capacitor banks function by storing electrical energy in an electric field, which can be released when needed. When connected to an electrical system, they can absorb reactive power, which is the power that oscillates between the source and the load without being consumed. By doing so, capacitor banks help to balance the power factor, stabilize voltage levels, and improve overall system efficiency.

B. Types of Capacitor Banks

1. **Fixed Capacitor Banks**: These are designed to provide a constant amount of reactive power compensation. They are typically used in applications where the load is predictable and stable.

2. **Automatic Capacitor Banks**: These systems can adjust the amount of reactive power compensation based on real-time load conditions. They are equipped with control systems that monitor the power factor and automatically switch capacitors in or out as needed.

C. Common Applications of Capacitor Banks

Capacitor banks are widely used in various sectors, including industrial, commercial, and utility applications. They are essential in manufacturing facilities, office buildings, retail spaces, power generation plants, and distribution networks.

III. Key Advantages of Capacitor Bank Products

A. Power Factor Improvement

1. Definition of Power Factor

Power factor is a measure of how effectively electrical power is being converted into useful work output. It is the ratio of real power (used to perform work) to apparent power (the total power flowing in the circuit). A power factor of 1 (or 100%) indicates that all the power is being effectively converted into work.

2. How Capacitor Banks Enhance Power Factor

Capacitor banks improve power factor by supplying reactive power to the electrical system. This reduces the amount of reactive power that must be supplied by the utility, thereby improving the overall power factor of the system.

3. Benefits of Improved Power Factor

An improved power factor leads to reduced energy costs, as utility companies often charge penalties for low power factor levels. Additionally, it enhances the capacity of the electrical system, allowing for more efficient operation and reduced strain on equipment.

B. Voltage Regulation

1. Importance of Voltage Stability

Voltage stability is crucial for the reliable operation of electrical equipment. Fluctuations in voltage can lead to equipment malfunctions, reduced efficiency, and even damage.

2. Role of Capacitor Banks in Voltage Regulation

Capacitor banks help maintain voltage levels by providing reactive power support during periods of high demand. This stabilizes the voltage and ensures that electrical equipment operates within its specified voltage range.

3. Impact on Electrical Equipment and Systems

By regulating voltage levels, capacitor banks protect electrical equipment from damage, enhance performance, and prolong the lifespan of devices such as motors, transformers, and other critical components.

C. Energy Savings

1. Reduction in Energy Costs

By improving power factor and reducing reactive power demand, capacitor banks can lead to significant energy savings. Lower energy consumption translates to reduced utility bills for businesses and consumers alike.

2. Increased Efficiency of Electrical Systems

Capacitor banks enhance the efficiency of electrical systems by minimizing losses associated with reactive power. This means that more of the energy consumed is converted into useful work, rather than being wasted.

3. Long-term Financial Benefits

The initial investment in capacitor bank products can be offset by the long-term savings achieved through reduced energy costs and improved system efficiency. Over time, these savings can lead to a substantial return on investment.

D. Reduced Transmission Losses

1. Explanation of Transmission Losses

Transmission losses occur when electrical energy is lost as it travels through power lines. These losses can be attributed to resistance in the conductors and the reactive power that must be supplied to maintain voltage levels.